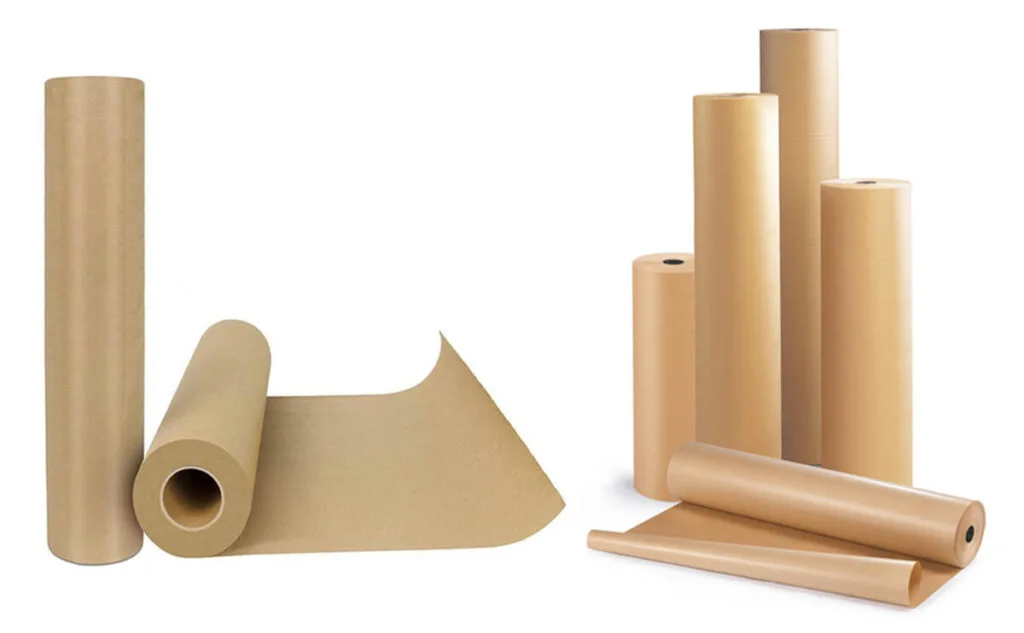

Efficient warehouse management is a critical factor in ensuring smooth operations and reducing operational costs for businesses. Pallet wraps, also known as stretch wraps, have emerged as an essential tool in optimizing warehouse processes. These versatile materials offer numerous benefits that contribute to maximizing efficiency in various aspects of warehouse management.

Secure Load Stability: Pallet wraps are designed to securely hold and stabilize items on a pallet, preventing shifting or toppling during storage and transportation. This ensures that products remain intact and undamaged, reducing the risk of losses due to breakage and enhancing overall warehouse efficiency by minimizing rework and replacement.

Time and Labor Savings: Using pallet wraps significantly reduces the time and labor required to prepare items for storage or shipment. Traditional methods such as strapping and taping can be time-consuming and require manual effort. Pallet wraps, on the other hand, can be applied quickly using automated machines, allowing warehouse staff to focus on other critical tasks.

Faster Inventory Management: Transparent pallet wraps allow for easy visual identification of items on a pallet. This accelerates the process of inventory management, as staff can quickly identify products without the need to unwrap them. As a result, order picking, restocking, and cycle counting become more efficient and accurate.

Protection from Environmental Factors: Pallet wraps provide a barrier against dust, moisture, and other environmental factors that can damage products during storage or transportation. By maintaining product integrity, businesses can avoid losses due to spoilage and minimize the need for quality control checks or reconditioning.

Streamlined Transportation: Securely wrapped pallets are less prone to damage during transit, reducing the likelihood of rejected shipments or returns. This streamlines transportation processes and enhances relationships with customers and suppliers, ultimately leading to improved supply chain efficiency.

Space Optimization: Efficient use of warehouse space is crucial. Pallet wraps help create stable and uniform loads, allowing for optimized stacking and storage of pallets. This not only maximizes the use of available space but also promotes safety by preventing pallet collapses.

Reduced Packaging Costs: Pallet wraps eliminate the need for additional packaging materials like boxes, crates, or excessive padding. This not only reduces material costs but also contributes to sustainability efforts by minimizing waste generation.

Customizable Strength and Stretch: Pallet wraps come in various strengths and stretch levels, allowing businesses to choose the most suitable option for their products. This customization ensures that items are adequately protected without unnecessary waste of wrapping material.

Conclusion: Pallet wraps play a pivotal role in maximizing efficiency in warehouse management. Their ability to secure loads, save time and labor, expedite inventory management, protect against environmental factors, and optimize transportation and storage processes makes them an indispensable tool for modern warehouses. By adopting pallet wraps, businesses can enhance overall efficiency, reduce operational costs, and deliver improved services to customers and partners within the supply chain.